More and more companies in horticulture around the world start working with Autonomous Growing. Why do they choose to start working with artificial intelligence (AI) in the greenhouse from a business perspective? Blue Radix asked three CEOs.

‘Autonomous Growing: win-win for team and company’

‘Autonomous Growing: win-win for team and company’

Article from | Blue Radix

More and more companies in horticulture around the world start working with Autonomous Growing. Why do they choose to start working with artificial intelligence (AI) in the greenhouse from a business perspective? Blue Radix asked three CEOs.

Using data and artificial intelligence makes it nowadays possible to control the growing of crops inside greenhouses autonomously. Blue Radix has been proving this in practice at numerous horticultural companies for some time now, using the Autonomous Growing system Crop Controller.

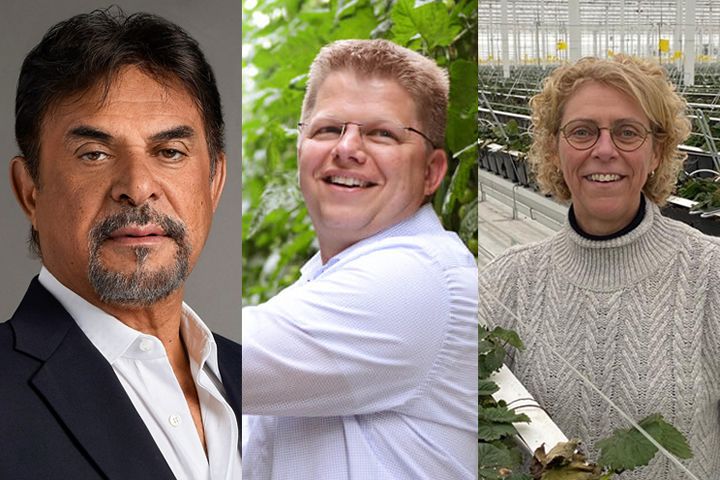

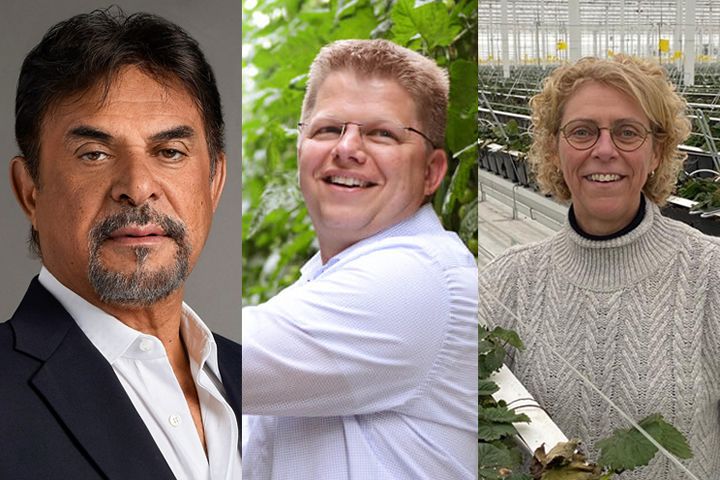

One of those companies is the American Village Farms. Village Farms grows tomatoes and cannabis on 92 hectares. The lack of sufficient growers is a big problem in the United States and Canada. “Finding world-class growers is an almost impossible task. Autonomous Growing solves that problem, provided you get everyone within the organization on board," says Mike DeGiglio, CEO of Village Farms (left on photo). “Because it should not be imposed by the CEO of the company. Only if it is widely embraced and seen as an important tool for the future, it can be a success.”

Personal service feels like partnership

The personal guidance from Blue Radix helps with this, DeGiglio believes. “At Blue Radix they know how it works and they can give the users of Crop Controller that bit of extra confidence and support. Also, some growers are a little more conservative than others and need an extra push. In any case, it's good if someone can look over your shoulder every now and then. But that personal service also ensures that the collaboration feels like a partnership that you enter together.”

Mike DeGiglio has a past in the aviation industry, where he sees parallels with Autonomous Growing. “Crop Controller is in fact the grower's co-pilot who ensures that he is not alone. And that co-pilot will continue to develop. Crop Controller is collecting more and more data, and becoming increasingly smarter. Ultimately, this should lead to the co-pilot developing into a captain and allowing you to hand over the stick at night, weekends, and holidays for a more balanced life. This evolution requires some patience and trust.”

Better yield

CEO Theo van Noord from Noordhuys Tomatoes (middle on photo) in the Netherlands firmly believes in the potential of AI to enhance crop cultivation. “AI solutions can store and process more information and data than a human. With this data, AI can make the best possible decision for the crop. A person is limited in processing information and therefore makes a decision with less complete information compared to AI solutions.”

Noordhuys Tomatoes has a total of 38.5 hectares of tomatoes spread over four growing locations. The company uses Crop Controller from Blue Radix at those facilities and CEO Van Noord is enthusiastic about it. “The system helps our growers to manage more area than before. This is possible because AI ensures that the climate is controlled at least as well as a specialist can do this. The grower also has more time for other tasks, allowing the company to work more efficiently. Autonomous growing also realizes even better results in terms of yield. Based on more information, fewer mistakes are made which helps the crop specialist to have a better grow management of the crop. Production increases more and more.”

Marion van Gog, CEO at Van Gog Kwekerijen (right on photo), agrees. The company grows cucumbers, tomatoes, peppers and strawberries in Germany and the Netherlands. According to Van Gog, Autonomous Growing is indispensable in order to further scale up production in the coming years. “Growers are becoming increasingly scarce and the people we employ are coming under increasing pressure. I therefore see Autonomous Growing as an important tool to support our growers in the greenhouses. Because it is more difficult to find new qualified people, we would like to keep our employees on board for a longer period of time. Thanks to Blue Radix's Autonomous Growing system, our growers can occasionally go home an hour earlier or take a weekend off. Overall, we can reduce the burden on our specialists, while they can now manage 20 hectares instead of 5 hectares. A win-win for the employees and the company.”

Growers enjoy working in this new way

Van Gog indicates that the company likes to be at the forefront of new developments, including Autonomous Growing. In 2023, Crop Controller was rolled out in Germany, followed this year by the locations in the Netherlands. “We also explicitly involve our employees in these changes and we see that they enjoy working in this new way. They do not see Artificial Intelligence as a threat, but rather as a support that only makes work more pleasant.” The expectations for the coming years are therefore high, Van Gog says. “One person can be responsible for more hectares. Repetitive tasks and analysis of data by employees will decrease and the system ensures fewer mistakes are being made. Yield results will improve even more.”

The social aspect of Autonomous Growing seems to be an important argument for the entrepreneurs to take the step. DeGiglio, of the American Village Farms, also points out the happiness of his employees as the main reason why he started with Crop Controller. “You should not underestimate the work of a grower today. It is so comprehensive that it requires attention seven days a week. You can no longer demand that of people, they also have a social life. We want our employees to enjoy their work and thanks to Autonomous Growing we can take the pressure off. This allows them to be home more often. If the family is happy, the employees are too. That also has a positive influence on the company as a whole, because happy people tend to work more effectively, and we can prevent them from leaving us.”

Keep making progress

Theo van Noord also foresees further improvements to the AI system in the coming years. “The Blue Radix model has a great appearance and is easy to work with. The program is improved through the feedback we can provide. Marion van Gog agrees. “With Blue Radix, companies can also actively think along and work on this relatively young development. Collecting data and perfecting the system takes time. But in the meantime, we as users can express our wishes and propose improvements. This will only ensure that the system fits in even better with practice.”

Van Gog envisions one portal in the future where climate, water, energy, and CO2 come together and that works seamlessly with all cameras and sensors in the greenhouse. “We have to get the most out of AI together. For me, the added value of Autonomous Growing is not so much in kilos of product, but more in making the work easier, so that we can continue to grow as a company even if we have fewer people available.”

The content & opinions in this article are the author’s and do not necessarily represent the views of AgriTechTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product